Aaron's Blog

Blog Post Categories

🏭🌐 Smart Manufacturing: How IoT and Industry 4.0 are Revolutionizing Production 🚀💡

“The Internet of Things is not a concept; it is a network, the true technology-enabled Network of all networks.” - Edewede Oriwoh

Today, we're going to take a closer look at the rise of IoT and Industry 4.0, and how smart manufacturing is revolutionizing production.

IoT, or the Internet of Things, refers to the network of devices and sensors that are connected to the Internet, allowing them to communicate and share data.

Industry 4.0, on the other hand, refers to the fourth industrial revolution, which is characterized by the integration of advanced technologies like IoT, artificial intelligence (AI), and big data into manufacturing processes. I would also argue that it’s a shift from manufacturing to knowledge and services work.

Together, IoT and Industry 4.0 are enabling smart manufacturing, which is transforming the way goods are produced and delivered. Here are some examples of how smart manufacturing is revolutionizing production:

Predictive Maintenance:

IoT sensors can be used to monitor equipment and detect potential problems before they occur. By analyzing data in real-time, manufacturers can predict when maintenance will be needed, and schedule repairs before equipment breaks down. This reduces downtime, improves efficiency, and saves money.

Quality Control:

IoT sensors can also be used to monitor product quality in real time. By tracking data on factors like temperature, humidity, and pressure, manufacturers can detect defects and errors early on in the production process, reducing waste and improving overall product quality.

Inventory Management:

IoT sensors can be used to monitor inventory levels and track the movement of goods throughout the supply chain. By having real-time visibility into inventory levels and logistics, manufacturers can optimize production schedules and minimize waste.

Remote Monitoring:

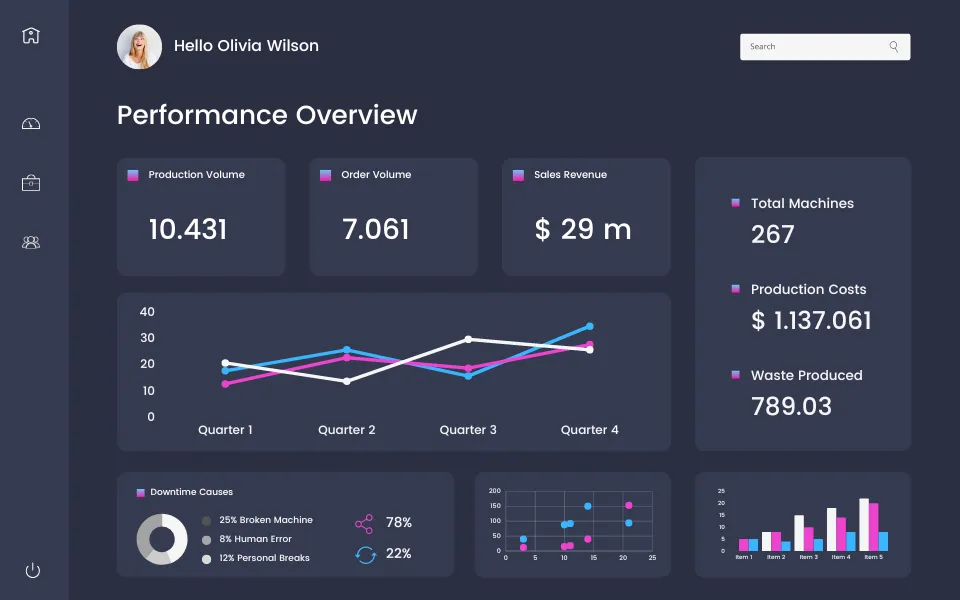

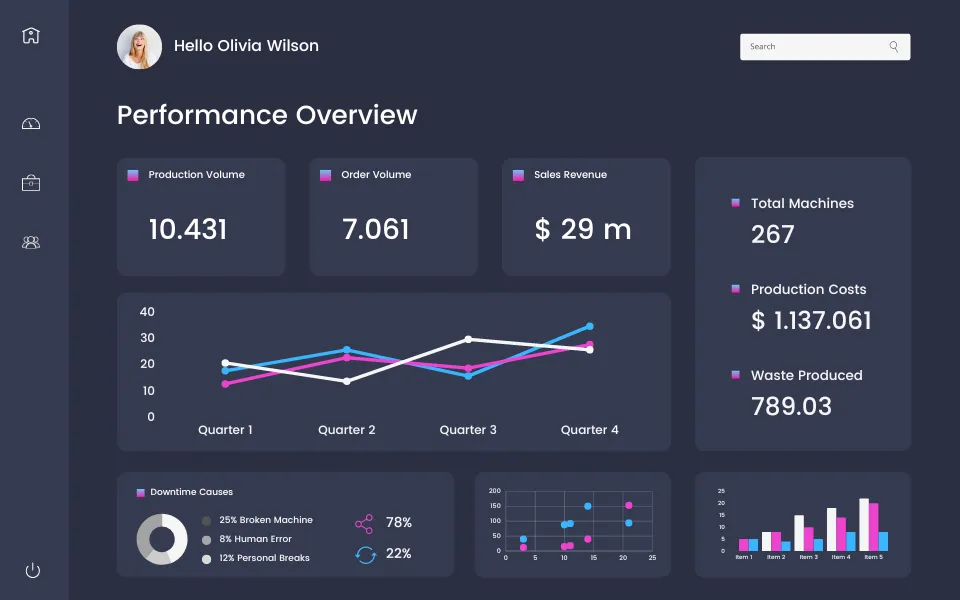

IoT-enabled devices can be remotely monitored, allowing manufacturers to track production and performance metrics from anywhere. This allows for more flexible and remote working arrangements, which can improve productivity and employee satisfaction.

Customization:

IoT and Industry 4.0 also enable greater customization in manufacturing. By leveraging data and advanced technologies, manufacturers can create personalized products and services that meet the unique needs and preferences of individual customers.

IoT and Industry 4.0 are enabling smart manufacturing, which is transforming the way goods are produced and delivered. By incorporating advanced technologies like IoT, AI, and big data into their processes, manufacturers can improve efficiency, reduce costs, and create new opportunities for customization and innovation.

As these technologies continue to evolve and become more accessible, it's important for manufacturers to stay up to date with the latest trends and best practices in smart manufacturing. By doing so, they can remain competitive, drive innovation, and create value for customers and stakeholders alike.

That's all for this week's newsletter. We hope you found this information helpful, and we'll be back next week with more insights and analysis on the latest trends in technology and business.

🏭🌐 Smart Manufacturing: How IoT and Industry 4.0 are Revolutionizing Production 🚀💡

“The Internet of Things is not a concept; it is a network, the true technology-enabled Network of all networks.” - Edewede Oriwoh

Today, we're going to take a closer look at the rise of IoT and Industry 4.0, and how smart manufacturing is revolutionizing production.

IoT, or the Internet of Things, refers to the network of devices and sensors that are connected to the Internet, allowing them to communicate and share data.

Industry 4.0, on the other hand, refers to the fourth industrial revolution, which is characterized by the integration of advanced technologies like IoT, artificial intelligence (AI), and big data into manufacturing processes. I would also argue that it’s a shift from manufacturing to knowledge and services work.

Together, IoT and Industry 4.0 are enabling smart manufacturing, which is transforming the way goods are produced and delivered. Here are some examples of how smart manufacturing is revolutionizing production:

Predictive Maintenance:

IoT sensors can be used to monitor equipment and detect potential problems before they occur. By analyzing data in real-time, manufacturers can predict when maintenance will be needed, and schedule repairs before equipment breaks down. This reduces downtime, improves efficiency, and saves money.

Quality Control:

IoT sensors can also be used to monitor product quality in real time. By tracking data on factors like temperature, humidity, and pressure, manufacturers can detect defects and errors early on in the production process, reducing waste and improving overall product quality.

Inventory Management:

IoT sensors can be used to monitor inventory levels and track the movement of goods throughout the supply chain. By having real-time visibility into inventory levels and logistics, manufacturers can optimize production schedules and minimize waste.

Remote Monitoring:

IoT-enabled devices can be remotely monitored, allowing manufacturers to track production and performance metrics from anywhere. This allows for more flexible and remote working arrangements, which can improve productivity and employee satisfaction.

Customization:

IoT and Industry 4.0 also enable greater customization in manufacturing. By leveraging data and advanced technologies, manufacturers can create personalized products and services that meet the unique needs and preferences of individual customers.

IoT and Industry 4.0 are enabling smart manufacturing, which is transforming the way goods are produced and delivered. By incorporating advanced technologies like IoT, AI, and big data into their processes, manufacturers can improve efficiency, reduce costs, and create new opportunities for customization and innovation.

As these technologies continue to evolve and become more accessible, it's important for manufacturers to stay up to date with the latest trends and best practices in smart manufacturing. By doing so, they can remain competitive, drive innovation, and create value for customers and stakeholders alike.

That's all for this week's newsletter. We hope you found this information helpful, and we'll be back next week with more insights and analysis on the latest trends in technology and business.

Copyright 2026. All rights reserved

Testimonials

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

JANE DOE

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.